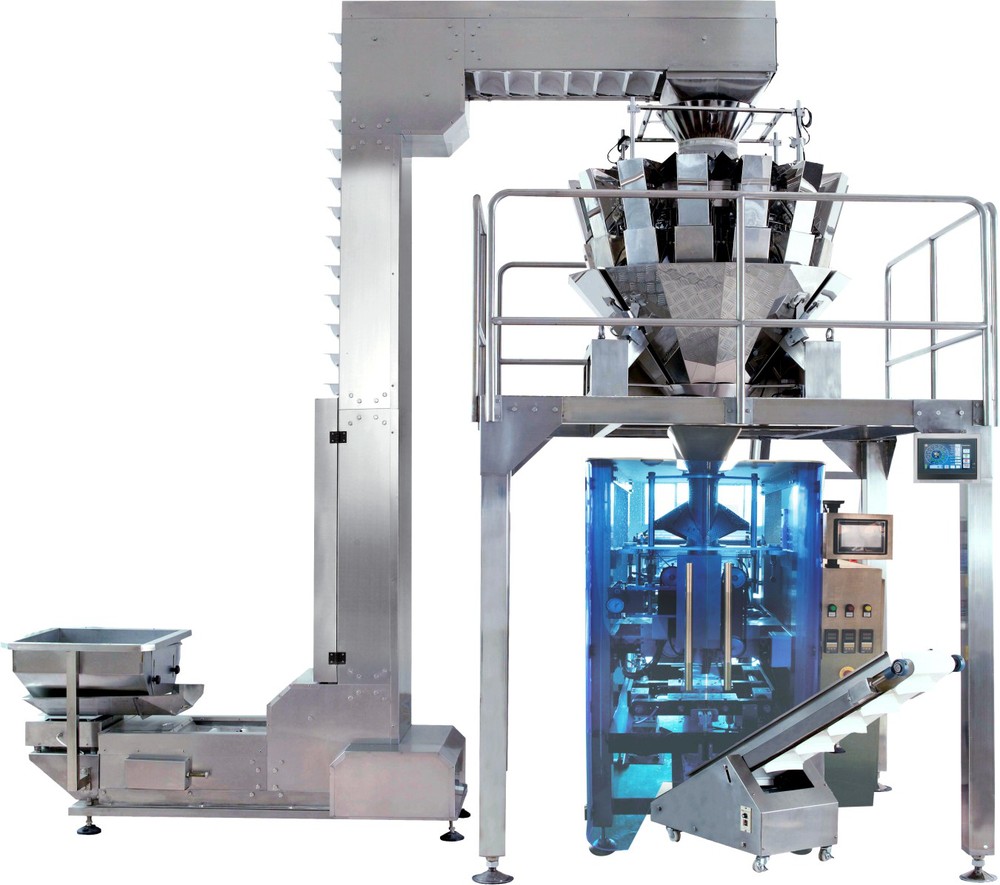

MODEL: CR-W-10H. Pneumatically operated fully automatic form fill & seal machine to pack “Chips” with multi head electronic load cell based weigh metric combination weigh filler. (10stations) fabricated with heavy duty angular structure weigher supported on channel platform, all contacts parts made out with SS, Machine is controlled by 1.HMI touch screen panel 2. Photo cell. 3.Nitrogen flushing

| FEEDING HEAD : | Multi head combination weigh filling system |

| PACKING RANGE : | Up to 1Kg |

| PRODUCTION SPEED : | 40 – 50 pouches / min |

| MACHINE CONTROL SYSTEM : | P.L.C |

| FILM WIDTH : | 525 mm |

| FILM THICKNESS : | 80 to 120 microns |

| FILM MATERIAL : | Any heat sealable laminated poly |

| SEALER HEATING SYSTEM : | Continues only |

| FILLING ACCURACY : | 0.1-0.5% |

| INNER CORE DIA. OF FILM ROLL : | 70mm |

| OUTER DIA. OF THE FILM ROLL : | up to 400mm |

| POUCH STYLE : | Centre seal pillow pouches |

| POUCH WIDTH : | up to 250 mm |

| POUCH LENGTH : | up to 350 mm |

| COMPRESSED AIR PRESSURE : | 6kg/cm² at 40c |

| AIR CONSUMPTION : | 14 CFM |

| POWER CONSUMPTION : | 1.5 kW/Hour |

| PEAK POWER : | 7.5 KW |

| POWER REQUIREMENT : | 3 Phase, 415 V, 50Hz plus Neutral |

| FILM GUARD MECHANISM : | Auto stop when film is exhausted |

| MACHINE DIMENSIONS IN ‘MM’ : | 3000 (H) x 1100 (W) x 2000 (Depth) |

| NET WEIGHT : | 1500 kgs (approx) |

0 Comment

Leave a Comment