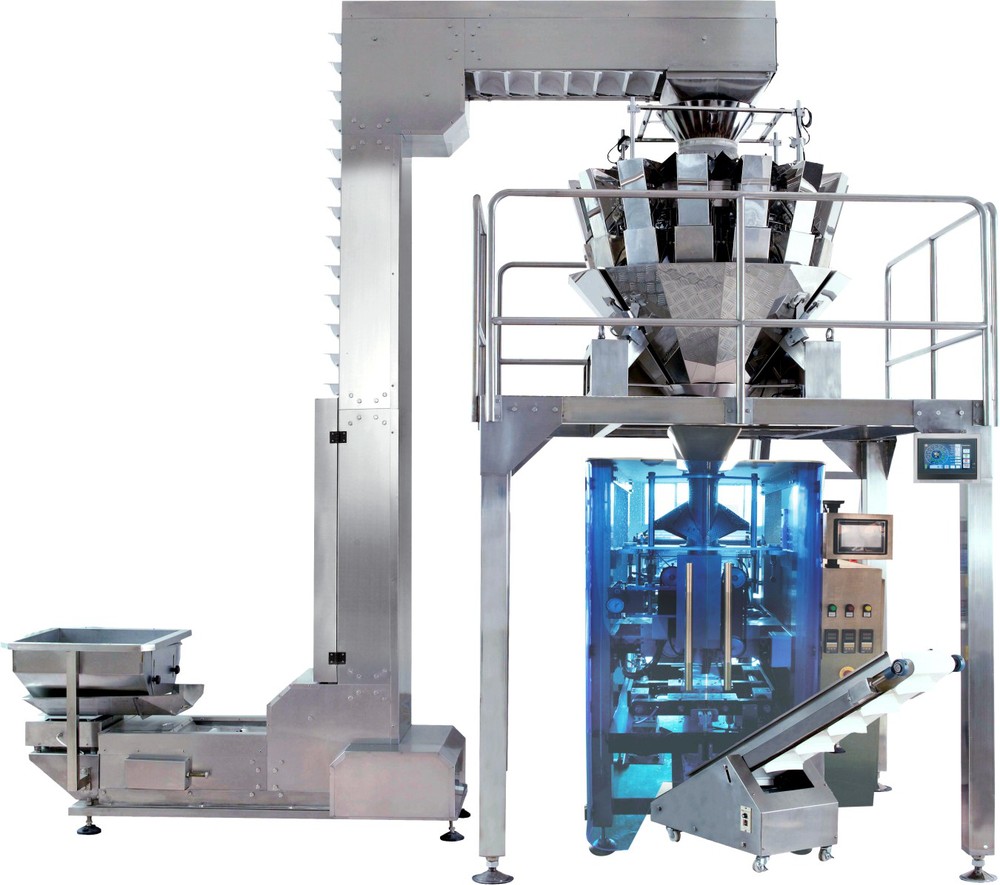

The product is feed into the top of the multi - head weigher, where a dispersal system distributes the product into a series of linear feed plates. Each Weigh head has its own precision load cell. These linear feed plates vibrate individually. The amplitude of vibration can be varied to increase or decrease the vibration depending on the characteristics of the product.

| FILM GUARD MECHANISM : | Auto stop when film is exhausted |

| POUCH COUNTER : | Provided |

| DATE PRINTING DEVICE : | 8 to 10 weeks from the date of advance received |

| PHOTO CELL : | Provided |

| FEEDING HEAD : | Multi head combination weigh filling system |

| PACKING RANGE : | 1kg to 5kg |

| PRODUCTION SPEED : | 40-50/1kg, 13 -18 pouches / min 5kg |

| MACHINE CONTROL SYSTEM : | P.L.C |

| FILM WIDTH : | 525mm |

| FILM THICKNESS : | 80 - 120 microns |

| FILM MATERIAL : | Any heat sealable laminated poly |

| SEALER HEATING SYSTEM : | Continues only |

| FILLING ACCURACY : | 0.1 to 0.3 % |

| INNER CORE DIA. OF FILM ROLL : | 70mm |

| OUTER DIA. OF THE FILM ROLL : | up to 350mm |

| POUCH STYLE : | Centre seal pillow pouches |

| POUCH WIDTH : | up to 250 mm |

| POUCH LENGTH : | up to 350 mm |

| COMPRESSED AIR PRESSURE : | 6kg/cm² at 40c. |

| AIR CONSUMPTION : | 14 CFM |

| POWER CONSUMPTION : | 5 kW / Hour |

| PEAK POWER : | 7.5 KW |

| POWER REQUIREMENT : | 3 Phase, 415 V, 50Hz plus Neutral |

| MACHINE DIMENSIONS IN ‘MM’ : | 3000 (H) x 1500 (W) x 2500 (Depth) |

| NET WEIGHT : | 2,200 kgs (approx) |

0 Comment

Leave a Comment